SINN Power

–

About

SINN Power offers energy solutions to provide people living near coasts all over the world with access to clean electricity to enable sustainable development and contribute to our planet at the same time.

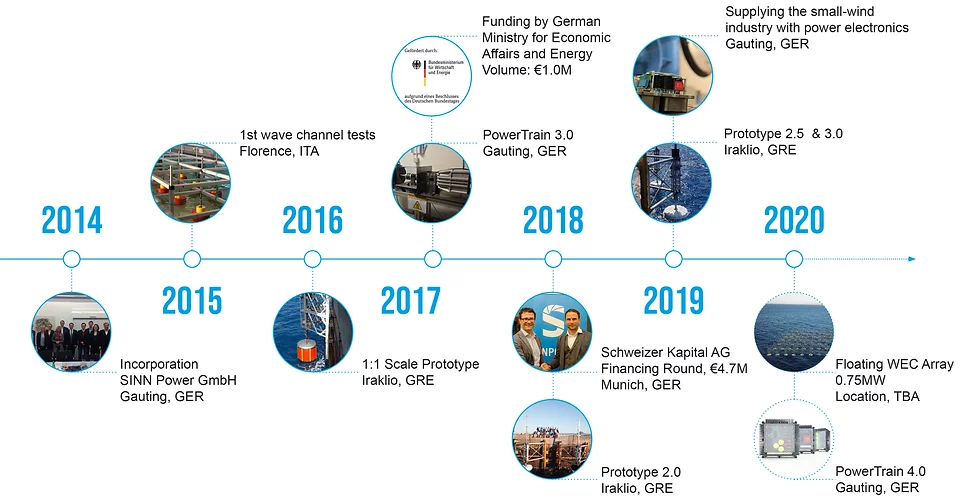

In 2014, Dr. Philipp Sinn founded the company SINN Power based on intense years of academic research. The main goal was, and still is today, to turn the unlimited power of ocean waves into clean and cost-efficient energy that is accessible for everyone.

Today, five years after SINN Power was founded, we operate fully functional prototypes at our research location in Heraklion and are on the verge of commercializing our technology.

–

–

–

Wave Energy Converters

Reliable, Cost-Efficient & Scalable

Available as a single structure-bound power generator or in an scalable network within a floating platform, SINN Power Wave Energy Converters (WEC) convert ocean wave energy into zero-emission electricity. The mass-producible standardized components can be easily transported in ISO containers and then be quickly assembled.

–

–

Structure-mounted WEC Module

The SINN Power Wave Energy Converter is an innovative system for generating electricity from ocean waves. The unique approach aims not to fascinate with complexity, but convinces with simplicity and effectiveness. Mass-producible standardized components guarantee cost-efficiency. Intelligent control software maximizes the electricity generation in every wave climate

–

–

–

Nominal power : 36 kW

Nominal voltage : 800 V

Swept area : 10 m²

Technology : Point absorber

–

–

Working Principle

Wave energy can harness the unlimited power of our oceans, simply by the up-and-down-movements of the waves

–

–

Operating Principle

The shaft moves the float up and down. Generator stacks are attached to the lifting rod connected to the float, which convert each movement of the lifting rod into electrical energy.

Key Facts

- 10 m lifting rod length

- 3.5 m stroke length

- Parallel connection enabled

- Allows installation both on fixed objects or in an array on open sea

- Consists of mass-producible standardized components

- Easy transport in ISO containers and simple assembly

- Remote diagnostic services

Related Files

For more detailed information and technical specifications please download the following documents: Factsheet

–

–

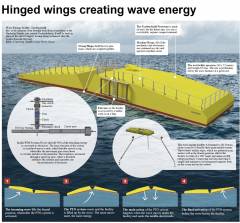

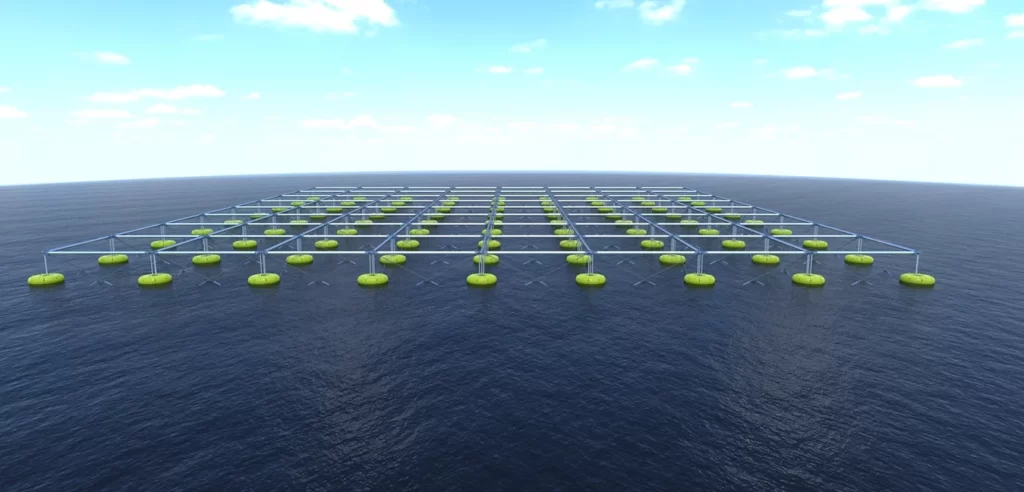

Floating WEC Platform

The WEC Platform enables large-scale power generation from wave energy by integrating a large quantity of WEC modules into one platform.

–

–

–

SINN Power’s Solution

The SINN Power wave energy converter (WEC) consists of individual modules, combined and connected in one rigid structure, allowing it to float on the ocean’s surface like an anchored ship.

The principle is easy: Through the up-and-down movements of the waves, the attached floating bodies of each module turn a lifting rod in motion. The result of friction: All attached generators produce electricity

–

–

SINN Power website

Carnegie Clean Energy

–

About

Carnegie is the owner and developer of the CETO® technology, which captures energy from ocean waves and converts it into electricity.

It use the latest advances in artificial intelligence and electric machines to optimally control the device and generate electricity in the most efficient way possible.

It have a long history in ocean energy with a track record of world leading developments.

–

–

–

–

–

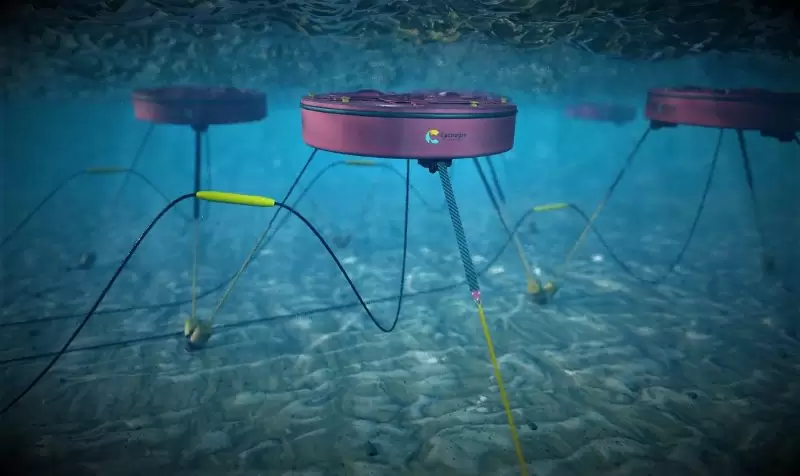

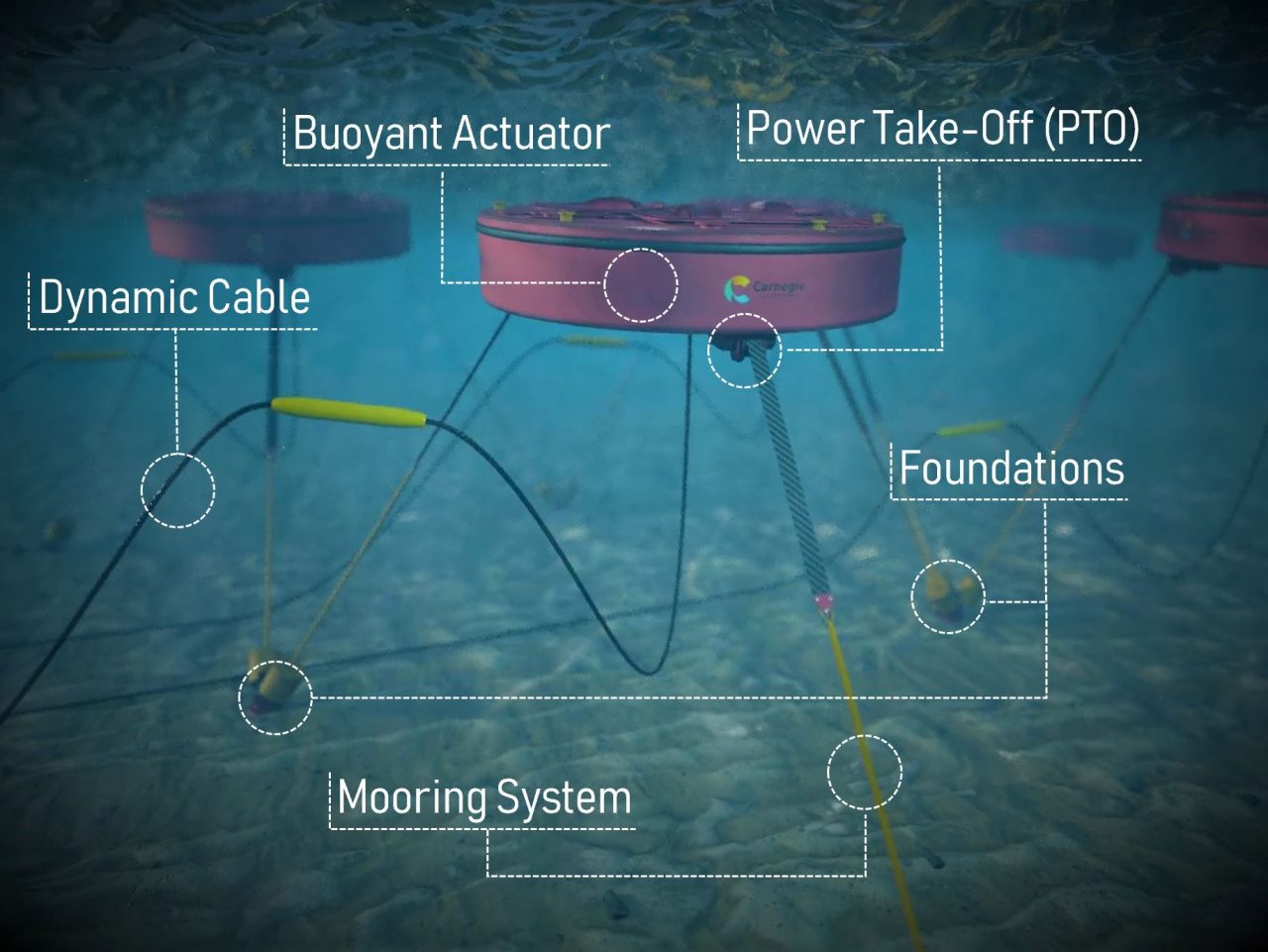

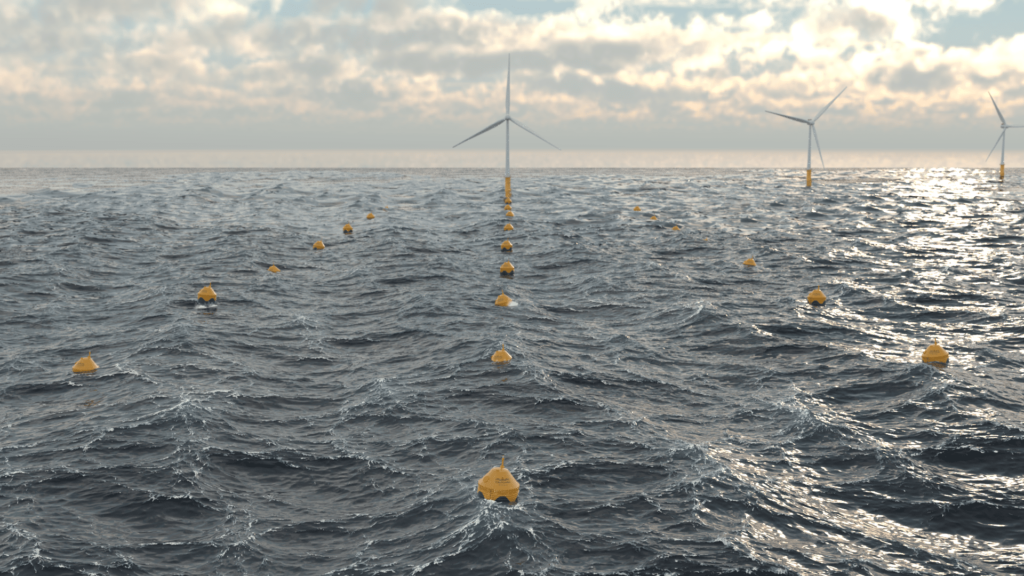

CETO Technology

Named after a Greek sea goddess, CETO offers the potential to revolutionise renewable power production globally. CETO harnesses the enormous untapped energy present in our ocean’s waves and converts it into grid-ready electricity. CETO is a unique, fully submerged, point absorber type wave energy technology. A submerged buoy sits a few metres below the surface of the ocean and moves with the ocean’s waves. This orbital motion drives a power take-off (PTO) system that converts this motion into electricity.

–

–

CETO Technology Characteristics

The CETO 6 design builds on intellectual property first lodged by Carnegie in 2013, incorporating on-board power generation and multiple moorings and power take-off modules. This associated US patent, granted on 6 November 2017, confirms the additional features as state of the art. These features boost power production and unit efficiency.

- Converts ocean wave energy into zero-emission electricity

- Environmentally friendly, has minimal visual impact and attracts marine life

- Fully-submerged and operates in deep water, away from breaking storm waves and beach-goers

- Tens of thousands of hours of in-ocean operational testing

–

–

CETO Advantages

- No Visual Impact – fully submerged

- Developed & Proven – over 10 years with onshore, wave tank and tens of thousands of hours of in-ocean testing

- Flexible -operates in variety of water depths, swell directions, tides & seafloor conditions

- Storm Survivability – fully submerged & extreme wave mitigation system

- Security – provides emissions free sustainable energy and water security to countries & islands

- Scalable – modular array design

- Clean – minimal environmental impact, co-exists with marine life.

- Desalination – zero-emission freshwater co-production allows pseudo energy storage

–

–

Carnegie Clean Energy website

Crestwing

CorPower Ocean

–

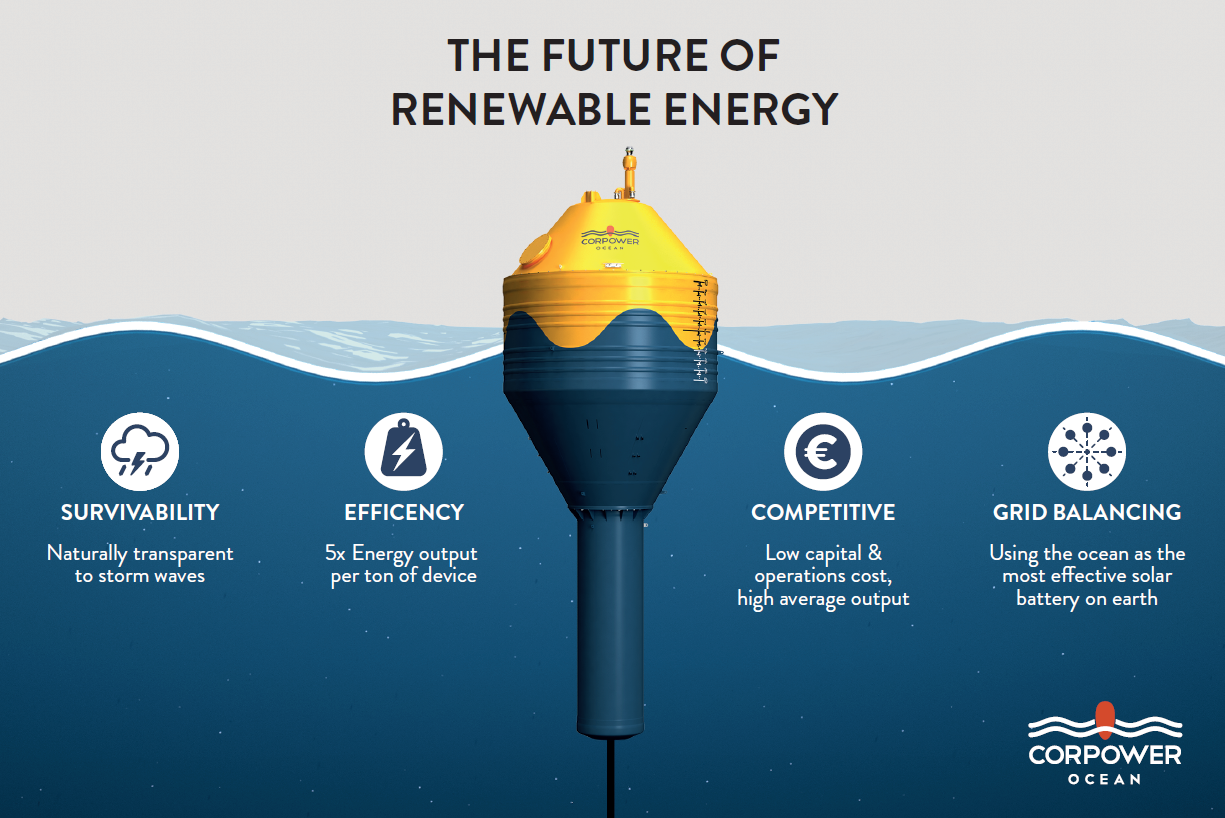

About CorPower Ocean

CorPower Ocean is a leading wave energy technology developer utilising forty years of ocean energy research to bring a new class of high efficiency Wave Energy Converters to market, enabling robust and cost-effective harvesting of electricity from ocean waves.

We are headquartered in Stockholm, Sweden with offices in Norway, Scotland and Portugal.

CorPower enjoys broad backing across Europe, with funders including EIT InnoEnergy, the European Commission, the Swedish Energy Agency, AICEP Global (Norte2020), Wave Energy Scotland, Midroc New Technology, ALMI Invest Greentech, SEB Greentech VC and additional private investors. End-users such as Iberdrola, EDP and Simply Blue Energy have been involved through all stages of development to ensure the product meets customer demands.

CorPower’s goal is to successfully introduce certified and warrantied WEC products in the market by 2024, allowing our customers to build wave farms using conventional project financing. Such a bankable product, with technology risks sufficiently eliminated, will be achieved by completing the last two steps of our structured market introduction process that has been ongoing since 2012.

–

–

CORPOWER’S WAVE ENERGY CONCEPT

–

–

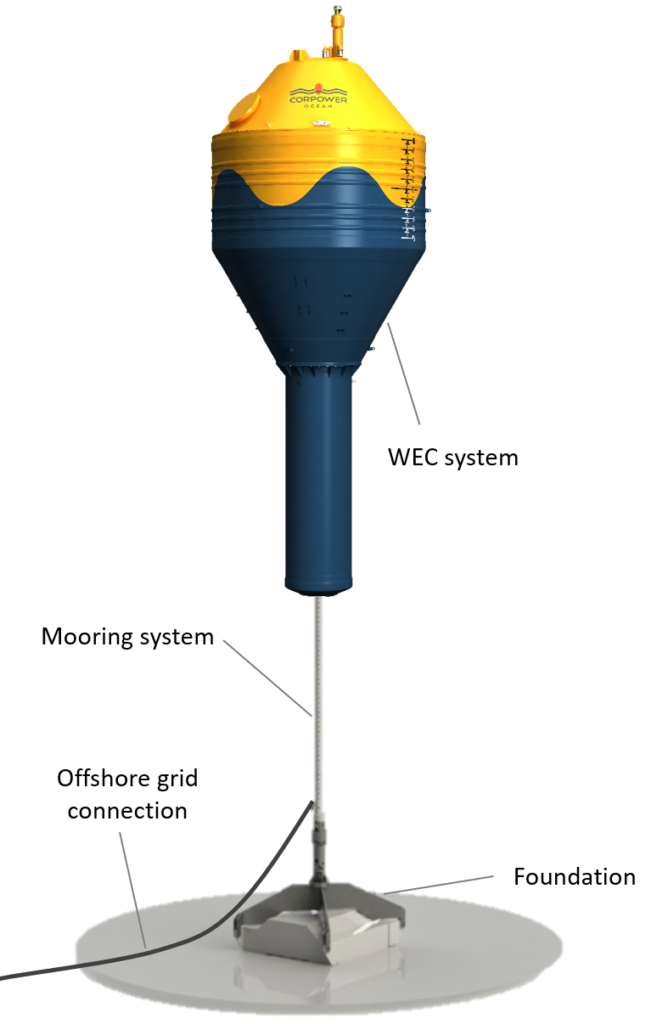

Our Wave Energy Converters are point absorber type, with a heaving buoy on the surface absorbing energy from ocean waves. The buoy is connected to the seabed using a tensioned mooring system. Novel phase control technology makes the compact devices oscillate in resonance with the incoming waves, strongly amplifying the motion and power capture. The system has improved survivability in storms, thanks to its inherent transparency to incoming wave energy in long storm waves.

The concept offers five times more energy per ton of device compared to previously known wave technologies. The high structural efficiency allows for a large amount of energy to be harvested using a relatively small and low-cost device, reducing the equipment (CAPEX) cost per MW capacity. The compact and lightweight WECs are also easy to install and maintain using low-cost vessels, bringing down operational (OPEX) costs. All together this provides competitive cost-of-energy.

Generators and power electronics are standard components known from the wind industry, enabling well known grid connection architecture. Our product concept is optimized for 10MW clusters, where the electricity is collected from an array of WECs into a collection hub. Each 10MW hub delivers grid quality electricity with standard 33/66kV electrical connection commonly used in offshore wind, with a single control and data acquisition interface over fibre and radio-link to the hub. Each WEC operate autonomously by a programmable logic controller located inside the device.

–

–

The wave farm concept is based on combining WEC clusters in arrays, connecting to a common grid export cable. The electrical architecture is chosen to allow export cables and substations to be shared with offshore wind, for projects aiming to take advantage of the complementary production profile between the wave and wind resource to deliver more continuous output from the array.

The array concept with many small units allows for mass production to drive down the cost per unit. An effective maintenance scheme is offered based on either replacing entire units or performing simple maintenance work offshore, improving farm uptime and providing overall reduction of O&M cost. The replacement scheme is enabled by the small physical size and limited cost per system, allowing simple handling and reasonable investment in spare units.

–

–

DESIGN PHILOSOPHY

–

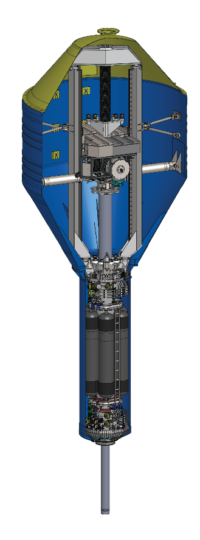

Inspired by the pumping principle of the human heart, CorPower uses stored pressure to generate energy from waves in two directions. The human heart uses stored hydraulic pressure to provide force for the return stroke, thereby only requiring the muscles of the heart to pump in one direction. In a similar way, CorPower WEC uses a pre-tension system to pull the buoy downwards.

It mimics the energy storage aspect of the human heart whereby the upward force of a wave swell pushes the buoy upwards while the stored pressure provides the restoring force drives the buoy downwards. This results in an equal energy production in both directions, and a lightweight system that is naturally transparent (detuned) unless actively controlled to match the wave climate.

The CorPower WEC converts energy from waves into electricity through the rise and fall as well as the back and forth motion of waves. A composite buoy, interacting with this wave motion, drives a Power Take Off (drive train located inside the buoy) that converts the mechanical energy into electricity. The light composite buoy is connected to the seabed through a power conversion module and a tension leg mooring system. In a conventional point absorber, the buoy follows the motion of the waves. The CorPower WEC on the other hand uses control technology to better leverage the motion of the waves by giving the oscillating motion optimal timing with each wave.

–

–

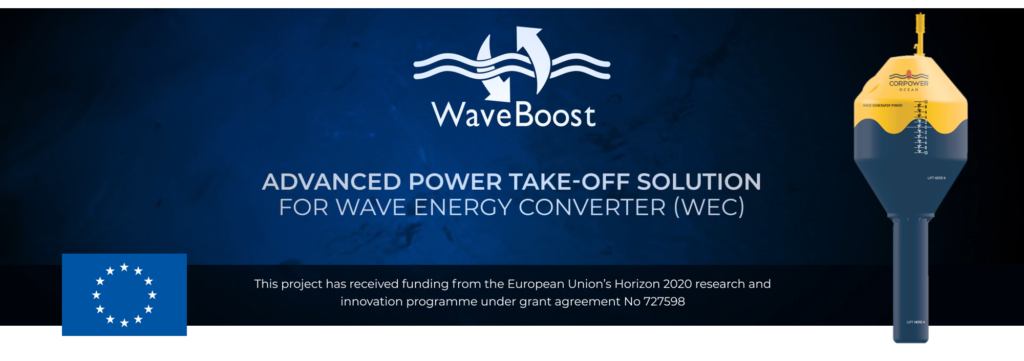

WaveBoost

–

Led by CorPower Ocean, the WaveBoost project designed and developed an advanced power take off (PTO) system allowing wave energy converters (WECs) to operate safer and more reliably in harsh ocean conditions while increasing annual electricity production.

A summary of the achievements is available in the Waveboost project video.

–

–

Challenges Addressed:

Two key challenges associated with harnessing wave energy are addressed by WaveBoost:

Storm Survivability: Reliable and efficient damping of wave energy devices is critical for robust operation in adverse weather conditions. Innovative machine elements will be demonstrated that in all operational conditions, including operation with faults, can provide safety and control of the machine. This effort aims at eliminating the risk of end-stop impacts, which has been a significant cause for failure in previous wave devices and can be a driver of large and costly structures.

Fluctuating power input from ocean waves: Solutions to smoothen power variability by innovative load shedding will be demonstrated aiming to improve the overall efficiency and economics of direct drive trains.

WaveBoost objectives:

This project’s main objective was to improve the reliability and performance of PTOs by developing and validating a revolutionary braking module with advanced control that can be coupled to different types of WECs. The WaveBoost module incorporates safety logic and energy redistribution functions beyond that of previous PTOs.

The specific project objectives and outcomes are:

- Increase reliability and survivability of WECs;

- Increase performance and reduce cost of WECs;

- Improve grid integration of wave energy;

- Increase system technology readiness;

- Reduce the lifecycle environmental impact.

Results

End of project press release: WaveBoost project improves performance and reliability of wave energy

By implementing a stepped design process and performing an exhaustive testing program using advanced rigs on both critical components and the full integrated system, the technology has been validated in a cost effective low risk manner using proven and calibrated testing infrastructure.

Key outputs from the project include:

–

- The design of the WaveBoost module is technology-neutral, to be applicable to a wide range of WECs representing potentially over 75% of the current market, hence its successful demonstration provides multiple opportunities for commercialization to impact the entire wave sector.

- Design of the advanced PTO, including an advanced braking system for greater control of movement and a 98% reduction on overall flow losses.

- Development of HIL-rig and test plans for the advanced PTO.

- FMECA and VMEA analysis of advanced PTO informing design and testing processes.

- Detailed modelling of advanced PTO within multiple wave energy applications.

- Accelerated testing of seals within a bespoke, state-of-the art Seal Test Rig, resulting in a 70% improvement on seal friction.

- Biofouling and corrosion testing in a real sea environment.

- Estimated 21.3% to 26.9% improvement in Annual Electricity Production (AEP), based on a target power matrix.

- LCOE analysis undertaken of three array sizes; 50MW, 300MW and 1GW. Estimated 18.0% to 29.3% reduction in LCOE.

- Lifecycle analysis undertaken of a 50MW array deployed in Scotland, resulting in a carbon intensity of 31.4gCO2e/kWh, comparable with other renewable technologies and over 10 times less than conventional gas turbines.

- Socioeconomic analysis undertaken of a 50MW array deployed in Scotland, resulting in €166M GVA and 2088 job years supported.

The project outcomes and results are disseminated for the benefit of the ocean energy industry through published reports. These reports can be downloaded on the CORDIS website and by clicking here: WaveBoost Results

Lasting impact:

The learnings from the WaveBoost project have been carried forward as CorPower Ocean move towards the manufacturing, dry testing and deployment of their next full scale C4 WEC.

WaveBoost partners

The WaveBoost project brings together a consortium of sector leaders from Sweden, Portugal and the UK:

- The European Marine Energy Centre (EMEC), UK

- EDP Innovação SA, Portugal

- CorPower Ocean AB, Sweden

- PMC Cylinders AB, Sweden

- The University of Edinburgh, UK

- WavEC Offshore Renewables, Portugal

- RISE Research Institutes of Sweden, Sweden

–

CorPower Ocean website

Bombora Wave

–

About Bombora

A culture of innovation has propelled Bombora since mWave™’s inception in a farm barn in Perth, Western Australia. Today, thanks to exceptional people, we are delivering a blueprint for multi megawatt scale, reliable and competitive wave energy converter technology.

Founded in 2012 in Perth Western Australia, Bombora is an award-winning ocean energy company. Bombora has established its European operations in Pembrokeshire, Wales in the heart of a dynamic, wave and tidal energy focused region and is currently progressing the 1.5MW mWave™ Pembrokeshire Demonstration Project supported by ERDF funding through the Welsh Government.

Bombora’s innovative mWave™ product produces environmentally friendly, consistent and cost competitive energy for commercial power generation in coastal locations throughout the world.

Bombora’s core business is the supply of the key mWaveTM components, the cell modules and Power Take Off unit. Individual project requirements will determine what additional products and services Bombora would supply. The project delivery package could be a combination of any of or all of the following: product, project development services, engineering consulting, operations and maintenance management services.

Bombora can deliver wave energy as a true alternative to complement today’s renewable energy mix.

–

–

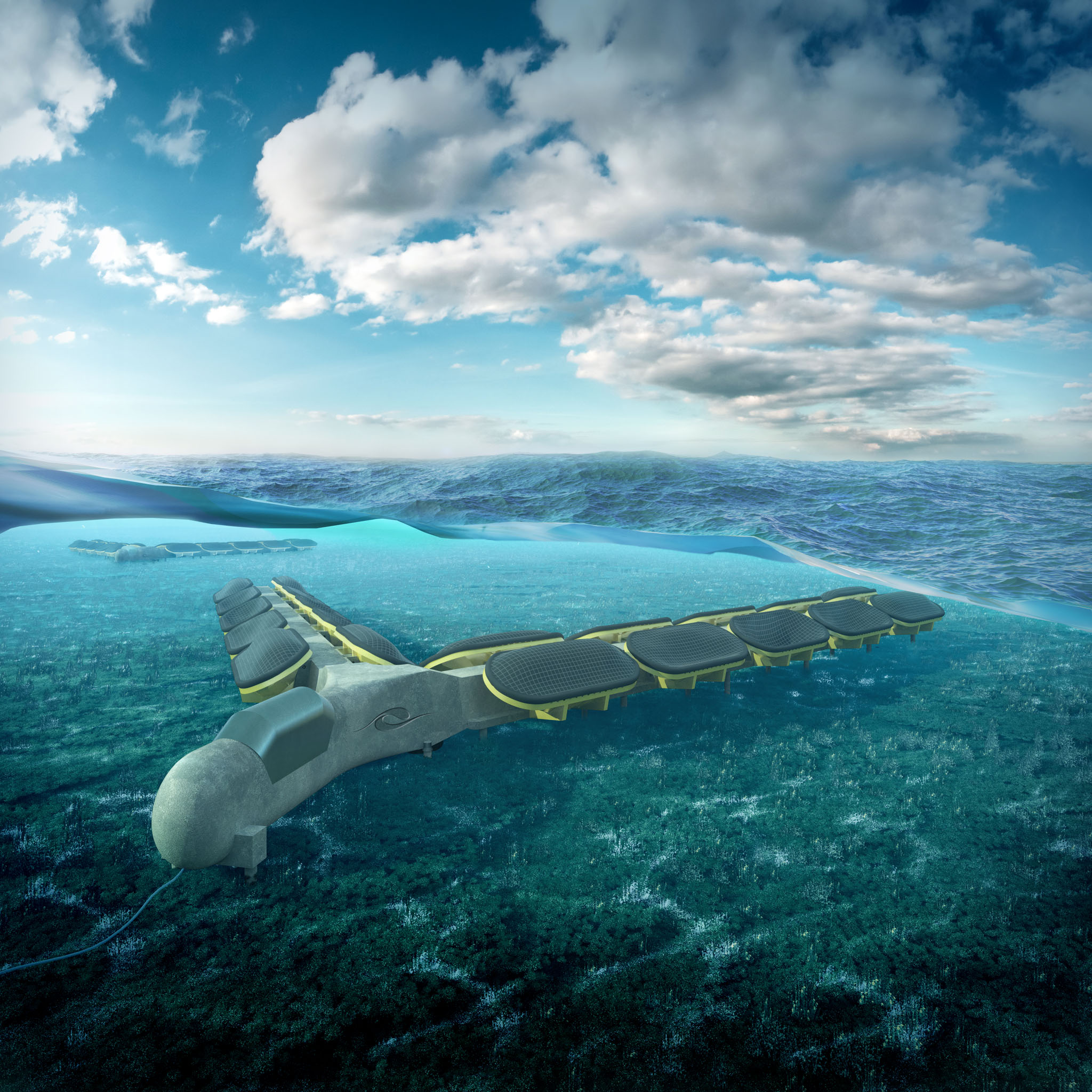

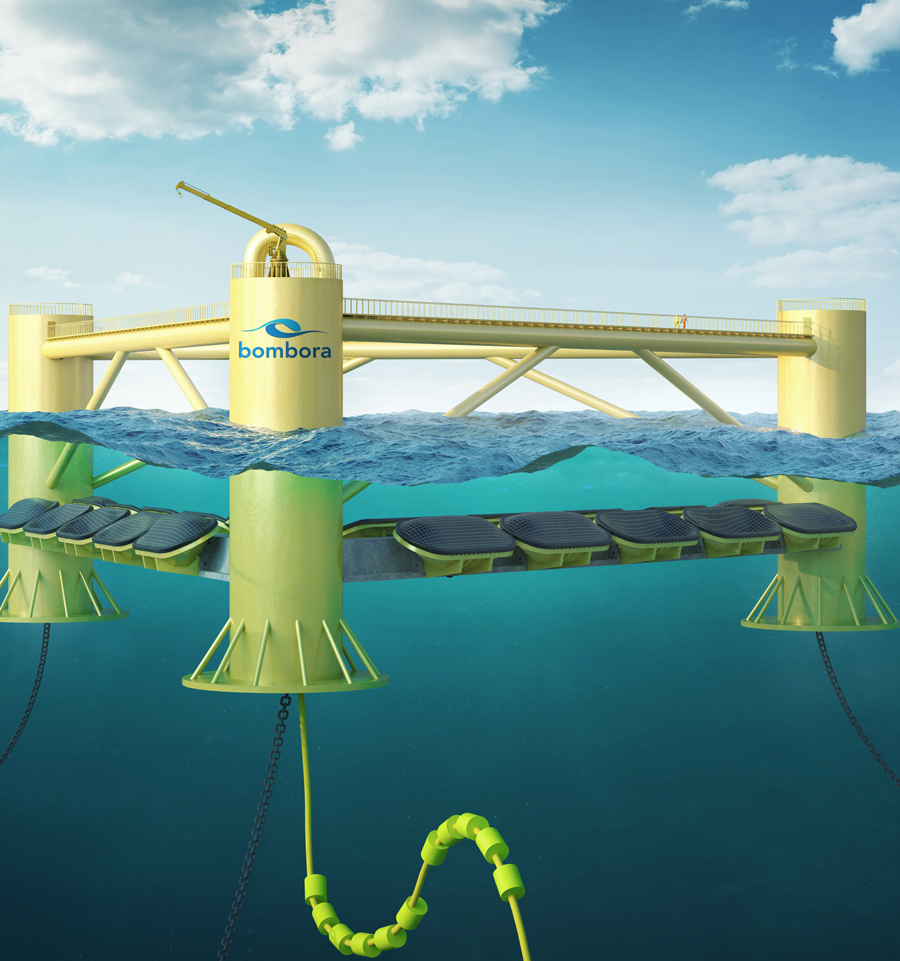

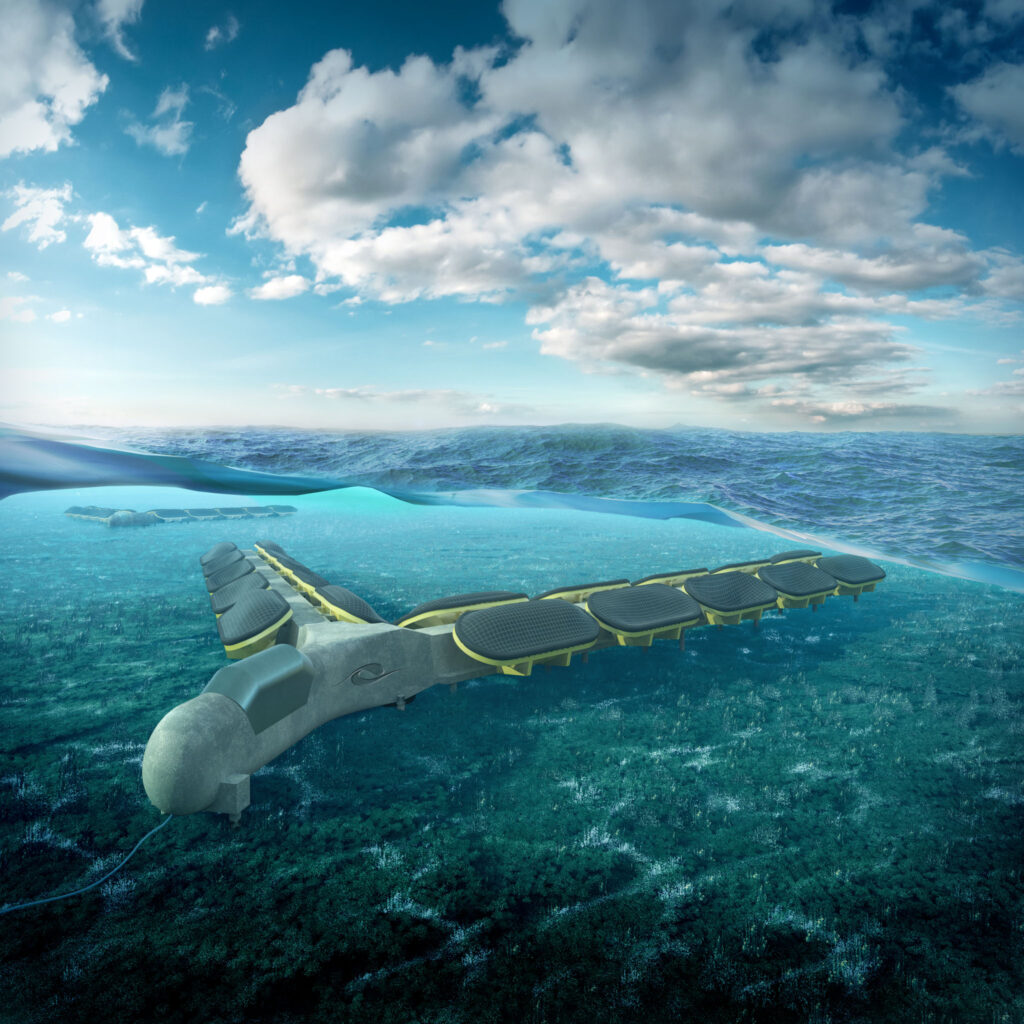

Technical overview

Bombora has developed a patented membrane-style wave energy converter, mWave™. mWave™ is unique among wave energy converters as it simultaneously addresses the cost of energy and ocean wave survivability challenges. This new approach proffers a new era for wave energy.

–

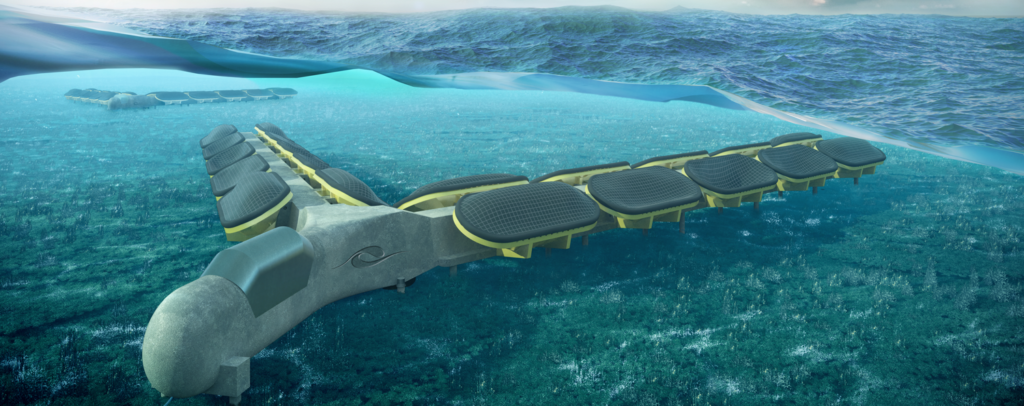

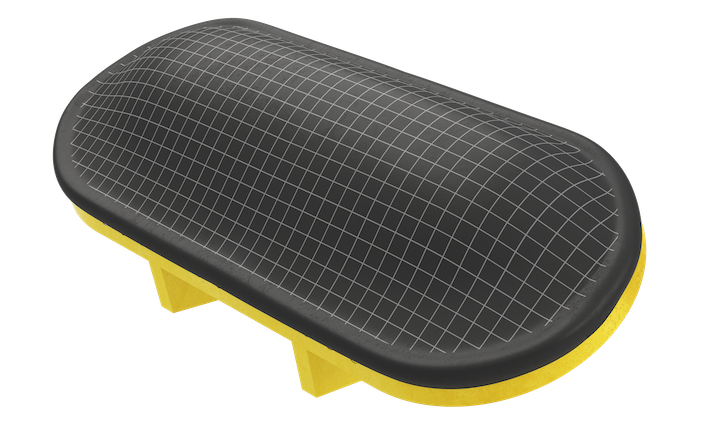

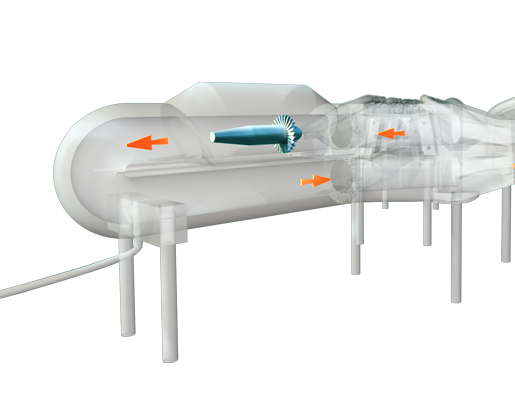

The Cell Module

mWave™ features a series of air-inflated rubber membrane covered concave cells mounted to a structure below the ocean’s surface creating an air-filled volume. To maximise energy capture, the structure is arranged at an angle to the incoming waves. As waves pass overhead, air is pushed out of each cell through a series of valves into a one-way air-duct . The cells are refilled once the wave has passed. The flexible membrane is made from industrial grade rubber. The longstanding use of similar materials in a range of marine applications has demonstrated the material’s reliability and longevity.

mWave™ has no external parts, other than the flexible rubber membranes. Our robust rubber cell membrane extracts power simply without complex mechanisms greatly reducing maintenance requirements. Our replaceable modular design streamlines maintenance, minimising downtime and maximising power output.

mWave™’s cell modules have the unique ability to shut down in extreme storm events. Limiting the loads reduces capital costs and improves the all important cost of electricity.

–

The Power Take-off

(PTO Turbine and Generator Module)

The air flow in the duct drives an unidirectional flow turbine which in turns drives a variable-speed generator. This type of turbine and generator are off-the shelf technology, even if adapted for the mWave™ operating envelope.

Electricity from the generator is transferred to the shore via a sub-sea cable. Following a process of power conditioning, the electricity is delivered into the local grid.

All operations and maintenance are achievable using existing service vessels used in both fixed bottom wind and offshore oil and gas industries.

mWave™ can be deployed on different platforms to suit a nearshore or offshore ocean environment. Find out more about Bombora’s Fixed mWave™ , Floating mWave™ and Integrated mWave™ platforms

°

–

°

°

mWave™ platforms

mWave™’s modular design enables the technology to be configured into a fixed structure or floating platform structure subject to deployment environment requirements

–

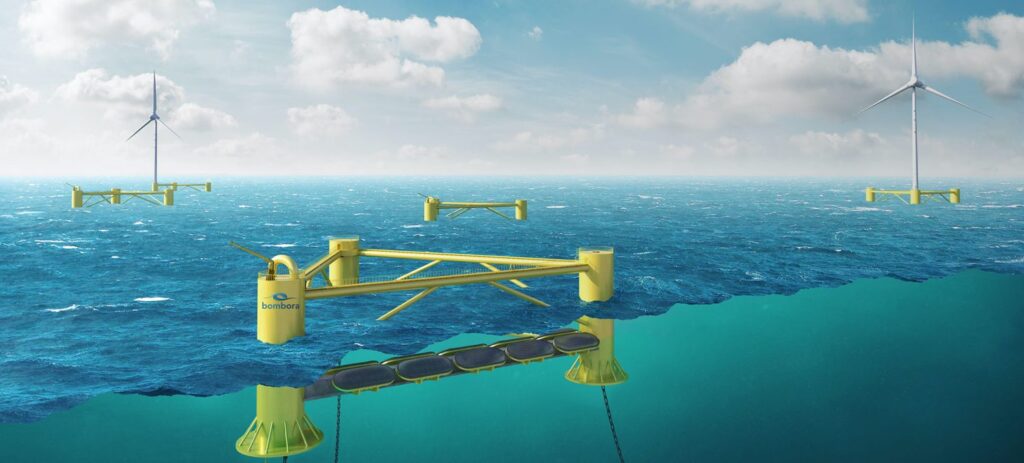

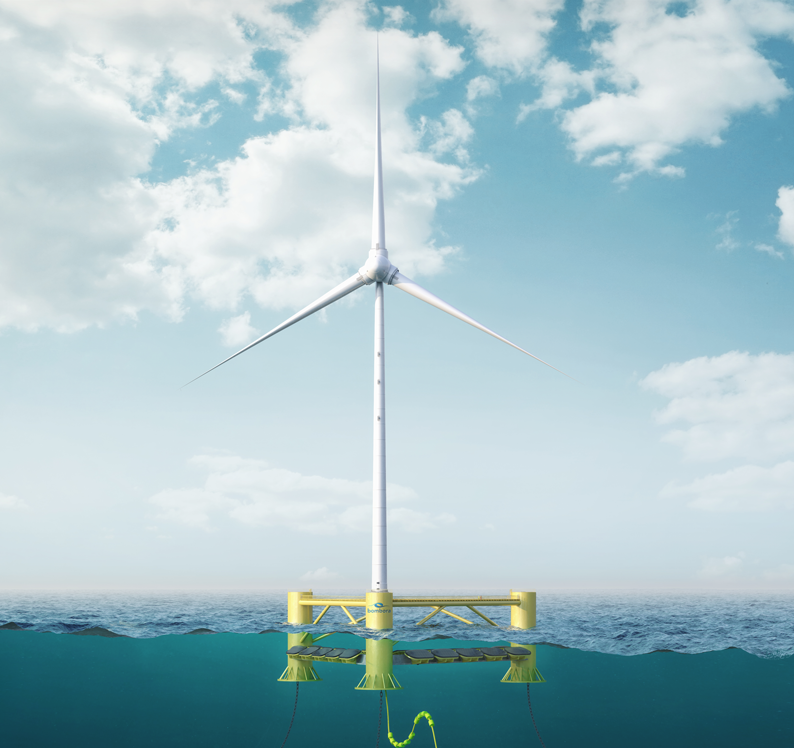

Integrated mWave™

mWave™ can be integrated into a single wind and wave platform.

An integrated wave and wind floating platform opens up development of the wave energy market on a utility scale. Early adopters of mWave™’s multi-MW integrated platform approach will achieve the required capacity, performance and output needed to deliver reliable, cost competitive clean energy.

4/6MW : Wave power rating (per mWave)

8-12MW : Wind power rating (per floating foundation)

50M+ : Water depths

In deep waters, mWave™ integrated with a wind turbine on a floating platform greatly increases seabed lease area capacity and output. Opportunity to share usage of offshore substation, grid connection and floating structure drives down OPEX and LCOE.

Find out more about the benefits of partnering wave and wind to deliver utility scale offshore wind projects.

Bombora’s collaborative project with the Offshore Renewable Energy (ORE) Catapult’s Marine Energy Centre of Excellence (MEECE) is carrying out a techno-economic appraisal of extending mWave™ technology, co-located and integrated, into an offshore environment.

–

Floating mWave™

+

mWave™ can be integrated into a floating platform structure.

A floating platform is the next-step in mWave™’s product development cycle to expand our global renewable megawatt power generation capacity and improve operational efficiency.

4MW : Wave power rating (per mWave)

20 Total number of cells

50M+ : Water Depths

In deep waters, mWave™ can be deployed, to exploit a much bigger floating platform opportunity, to deliver utility scale offshore wave projects and optimise wind farm output when co-located. The application of mWave™ to a floating platform provides a potential solution to existing offshore Oil and Gas operations looking to electrify platforms.

Bombora’s collaborative project with the Offshore Renewable Energy (ORE) Catapult’s Marine Energy Centre of Excellence (MEECE) is carrying out a techno-economic appraisal of extending mWave™ technology, co-located and integrated, into an offshore environment.

–

Bottom Fixed mWave™

°

Bombora’s Fixed mWave™ product delivers a clean renewable energy source to island nations and coastal regions, making a low carbon future a sustainable reality.

3MW Wave power rating (per mWave)

20 Total number of cells

10-25M Water depths

mWave™ is positioned approximately 10 meters beneath the ocean surface to maximise the energy captured from incoming waves. A fixed bottom mWave is completely invisible once installed and poses no risk to leisure vessels traveling on the ocean surface above.

Click here for more information on mWave™’s unique patented technology, Bombora’s energy solutions or information about the full scale, fixed bottom 1.5MW Pembrokeshire demonstration project.

–

–

Bombora Wave website

Wave Swell

Wave Swell is a developer of world leading proprietary technology which works to convert the energy in ocean waves into clean and emissions free electricity

–

Uniwave®

The Wave Swell Energy (WSE) technology is based on the well-established concept of the oscillating water column (OWC).

–

–

The OWC is an artificial blowhole consisting of a chamber that is open underneath the waterline. As waves pass the OWC, the water rises and falls inside, forcing the air to pass by a turbine at the top of the chamber. This turbine generates electricity.

Previous OWC technologies have all been bidirectional. The WSE technology, however, operates unidirectionally. This results in the WSE turbine being simpler, more robust and reliable, and exhibiting a higher energy conversion efficiency. The only moving parts in the technology are the turbine and bespoke valves, all of which are well above the water line. There are no moving parts in or below the water.

–

A world first project

WSE has deployed its 200kW wave energy project on King Island, Tasmania, adjacent to the harbour at the township of Grassy.

–

–

The unit was installed at Grassy, King Island, on January 10, 2021. It has since been commissioned, exporting its first power into the King Island grid on June 18, 2021. These are significant events for WSE’s shareholders and stakeholders.

WSE has worked with Hydro Tasmania, the island’s energy and network provider, to connect the unit to the local grid, and is now delivering energy from the project into the existing network. Hydro Tasmania will separately monitor the energy produced by the unit to ensure it meets the requirements of the King Island grid.

The wave energy produced will complement Hydro Tasmania’s existing hybrid grid, further diversifying the renewable sources and reducing diesel consumption on King Island.

The UniWave200 is now contributing to the mix of energy resources used to power the homes and industries of King Island.

–

–

–

What is the King Island Project Expected to Achieve?

The primary purpose of Wave Swell Energy’s (WSE) UniWave200 King Island project is to validate the models entailed in the various stages of the technology’s power conversion process.

–

–

This will be achieved in a comprehensive “wave to wire” fashion via the following modules:

- wave to pneumatic power – by validating the Australian Maritime College (AMC) physical scale model testing results in a full-scale ocean environment

- pneumatic to mechanical power – by validating the turbine efficiency model via a full-scale WSE turbine operating in a UniWave200 device in the real ocean

- mechanical to grid – by validating the electrical model via a full-scale electrical system installed in a UniWave device operating in the real ocean

These results will provide WSE with a baseline and the tools and inputs from which to develop the technology further as part of Project Bluefire, the company’s planned technology enhancement program.

The AMC model tests, conducted at the institution’s test tank facilities in Launceston, provide a detailed matrix of pneumatic power1 production across a range of different combinations of model scale wave height and period2. The King Island unit is expected to encounter this same range of wave conditions at full scale at the Grassy site.

A direct comparison of the King Island unit’s pneumatic power with the corresponding results of the AMC model tests will allow the confirmation of the UniWave200’s pneumatic power performance matrix3.

The King Island project is also designed to confirm the performance and conversion efficiency of the WSE turbine4. This bespoke turbine has been designed by a leading expert in the field of turbine design, based in the US.

Additionally, the King Island project will provide data that enables a refinement of the WSE electrical control system. The purpose of this system is to efficiently convert the mechanical energy of the turbine shaft into electricity, minimising energy wastage, and maximising output. This electrical process incorporates a short-term storage facility, utilising state-of-the-art ultra-capacitors, to provide a smoother delivery of electrical energy to the grid.

When the pneumatic power, turbine conversion efficiency, and electrical conversion efficiency matrices are combined with the frequency of occurrence matrix5 for a given site, an accurate estimate of the unit’s power production can then be calculated for that site. In this way, the results from the King Island project will make it possible to accurately predict the total conversion efficiency6 and power output of the WSE technology at any site in the world for which comprehensive wave data7 is available.

The validation and results from these three stages of the process, whereby energy from the waves is converted into electricity, will be the cornerstone of the inputs into Project Bluefire. The outcome of Project Bluefire is expected to be a more efficient and lower cost technology that is more widely applicable in terms of depth and geography.

Finally, the King Island project will be a tangible demonstration of the ability of the WSE unidirectional OWC technology8,9 to produce useable electrical energy capable of being incorporated into an island grid. It will also provide invaluable information and experience related to the unit’s day-to-day and long-term operation and maintenance.

King Island was chosen as a project site for two primary reasons – the wave climate and Hydro Tasmania. The wave climate in the region is amongst the best in the world. And, Hydro Tasmania, being a world leader in the integration of renewables into island grids, provides the project with a virtually unparalleled level of relevant expertise. This will prove significant in demonstrating the technology’s value to remote island grids.

Grassy, on the east coast of King Island, was chosen as the specific project site for additional reasons. As the main commercial harbour for the island, the general site already has the necessary electrical and other infrastructure required by the WSE project. And, being on the east coast of the island, the wave conditions that will be encountered are expected to cover the full range, from small to large, needed to validate the AMC model tests. Given this project involves a demonstration unit, there is as much to be learned from the operation and maintenance of the unit as there is from the production of power. The Grassy location provides the ideal conditions required for regular and easy access for operating the unit, as well as delivering the range of wave conditions necessary to fully test the device.

Importantly, the King Island project is not aimed at maximising the power production of the unit. Doing so would require a more energetic wave location, such as the west coast of the King Island. Future projects, incorporating the improvements from Project Bluefire, will be located in more energetic wave regimes to maximise energy production.

Glossary of Terms

- Pneumatic Power: Power measured at the pneumatic stage of the conversion chain given as the product of the volume flow rate (m^3/s) with the differential pressure (Pa) between the OWC chamber and atmosphere.

- Wave Height and Period: Wave height is the vertical distance between the wave crest and trough. Wave period is the time between two wave crests.

- Pneumatic Power Performance Matrix: A two-dimensional graphical representation of the pneumatic power (pressurised air flow) corresponding to the sea state (a combination of a specific wave height and period).The matrix normally consists of height on the vertical axis and period on the horizontal axis.

- Turbine Conversion Efficiency: The proportion of pneumatic power the rotating turbine converts to mechanical power.

- Frequency of Occurrence Matrix: For a given location, the frequency (how often) each sea state occurs is known as the Frequency of Occurrence Matrix.

- Total Conversion Efficiency: The proportion of wave power that is converted into electrical power across all stages of the energy conversion process.

- Wave Data: The sea state collected at a given location that allows for the Frequency of Occurrence Matrix to be populated (filled in).

- OWC (Oscillating Water Column): An oscillating water column consists of a large chamber that sits partially below the water and partially above, with a ‘mouth’ or entry duct open below the water line, and a small aperture open above. The chamber acts like an artificial blowhole, with energy from the waves entering and leaving the mouth, and energy in the air flow entering and leaving via the aperture, in which is housed a turbine.

- Unidirectional OWC: A variant of OWC technology that is unique to Wave Swell Energy and protected by an international patent. The technology enables simple rectification of air flow so that a more efficient and robust unidirectional air turbine can be used for pneumatic to mechanical energy conversion. Temporary energy storage in the water column is the key to why this concept works and explains why the energy is not being lost by venting the air chamber.

–

Wave Swell website

Mauritania Wave Energy Potentials (details)

–

Mauritania has one of the richest coasts in the world in terms of fish wealth. The Mauritanian coast extends 754 km long on the Atlantic Ocean. The Mauritanian beach has strong waves all year round.

In this article, you will discuss the potentials of wave energy in Mauritania, and can it bring about sustainable development?

–

–

MAURITANIA ENERGY’S STATISTICS

Mauritania generates 1,139,000 MWh of electricity as of 2016

–

FOSSIL FUELS ( 72%)

–

820,000 MWh

–

–

Hydroelectricity (16%)

–

180,000 MWh

–

–

Wind Energy (9.13%)

–

104,000 MWh

–

–

Solar Energy (3.07%)

–

35,000 MWh

–

–

Electricity access

electrification – total population: 32% (2019)

electrification – urban areas: 56% (2019)

electrification – rural areas: 4% (2019)

Electricity – production

1.139 billion kWh (2016 est.)

Electricity – consumption

1.059 billion kWh (2016 est.)

Electricity – installed generating capacity

558,000 kW (2016 est.)

–

–

Wave Energy Potentials in Mauritania

–

–

Mauritania has a beach overlooking the Atlantic Ocean with a length of 754 km. The average wave power on the Mauritanian coast is estimated at 17.5 kilowatt-hours per meter, meaning that the waves on the Mauritanian coast produce more than 300,000 megawatts every 24 hours, while the total electricity production in Mauritania is estimated at 3000 megawatts, For every 24 hours. that is, the wave energy produces 100 times the country’s total electricity production, or in other words, utilizing 1% of the wave energy at the Mauritanian coast will be sufficient to cover the country’s electricity needs by 100%.

Mauritania has 754 Km of coastline on the Atlantic ocean

Coastline (km) : 754

Coastal population percentage (%) : 55

The average wave power on the coast (kw/m) : 17.5

Wave energy theoretical potentials (Twh/year) : 115

Wave energy applicable potentials (Twh/year) : 6

Electricity consumption : 1.059 TWh (2016 est.)

wave energy index (%) : 566

–

–

Wave energy for developing of the artisanal fishing sector in Mauritania

–

–

Fishing is an important sector of the Mauritanian economy. All per year it produces up to 10% of GDP and represents up to 50% of the country’s exports. Total catch in Mauritania Water is estimated at 900,000 tons. About 63% of this It consists of small pelagic fish species that live near ocean surface.

The fishing industry directly employs 42,000 to 43,000 people including 80% in the artisanal fishing sector.

For the people of Mauritania and the West Africa provides a cheap source of protein, vitamins and essential micronutrients. However, annual per capita fish consumption in Mauritania is less than 6 kilograms, and about 27% of the population is classified as food insecure.

The problem of lack of electricity is an obstacle to the development of coastal communities. Providing electricity will be important for the development of the fishing industry in Mauritania.

Provides effective artisanal fishing The ability to enhance and secure food security in the country without increasing pressure on fisheries.

–

–

Offshore facilities (breakwaters ) that can be exploited for the installation of Wave energy converters

–

We will review here four seaports in Mauritania, each of which has breakwaters, we will calculate an approximate calculation of the capabilities of wave energy at these facilities and calculate the amount of electricity that will be produced by wave energy convertors if it installed on these facilities .

Port of Nouakchott , Port of Nouadhibou , Port of Tanit , port of N’diago .

–

–

–

- Autonomous Port of Nouakchott Port of Friendship

Nouakchott is the capital and largest city of Mauritania. It is one of the largest cities in the Sahel. The city also serves as the administrative and economic center of Mauritania .The metro area population of Nouakchott in 2021 was 1,372,000 .

–

–

The Friendship Port (Port de l’Amité) is an artificial deep-water port located in Nouakchott, Mauritania.

As the location is not a natural harbor, concrete block breakwaters had to be used to create a safe location for the ships. Plans are being made to increase its capacity.

The port of Nouakchott has a breakwater with a length of 200 meters and perpendicular to a berth of length 250

–

breakwater + berth ( meter ) = 450 m

The average wave power on the coast (kw/m) :

17.5 (Kilowatt /meter)

The total wave energy per year on the breakwater and the berth :

69,000 (MWh/year)

The efficiency of wave energy conversion 30% with using 100% of breakwater length :

20,700 (MWh/year) ~ 1.95%

of the total electricity consumption 1,059,000 MWh (2016)

–

–

–

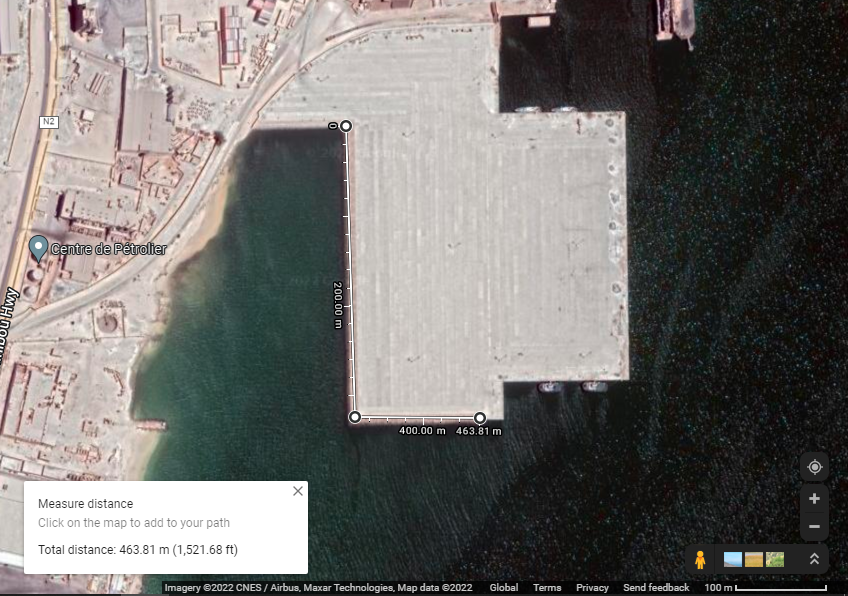

2. Port of Nouadhibou

Nouadhibou : is the second largest city in Mauritania and serves as a major commercial center. The city itself has about 118,000 inhabitants expanding to over 140,000 in the larger metropolitan area. Processing iron ore forms the largest industry in Nouadhibou, although the overall major economic activity is fishing

–

–

Port of Nouadhibou breakwater

–

breakwater + berth ( meter ) = 460 m

The average wave power on the coast (kw/m) :

10 (Kilowatt /meter)

The total wave energy per year on the breakwater and the berth :

40,000 (MWh/year)

The efficiency of wave energy conversion 30% with using 100% of breakwater length :

12,000 (MWh/year) ~ 1.13% of the total electricity consumption 1,059,000 MWh (2016)

–

–

–

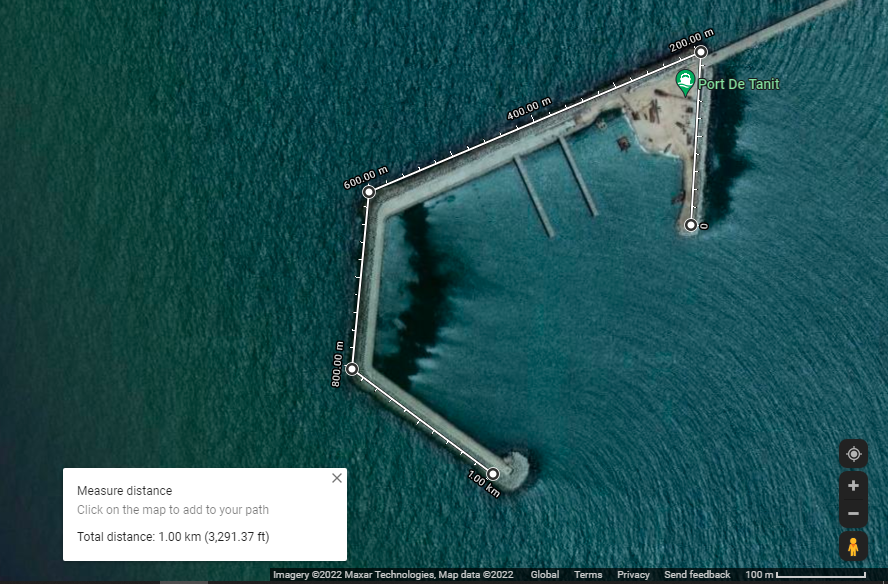

3. Port Tanit

–

Port Tanit breakwater

–

breakwater + berth ( meter ) = 1000 m

The average wave power on the coast (kw/m) :

17.5 (Kilowatt /meter)

The total wave energy per year on the breakwater and the berth :

153,300 (MWh/year)

The efficiency of wave energy conversion 30% with using 100% of breakwater length :

46,000 (MWh/year) ~ 4.35%

of the total electricity consumption 1,059,000 MWh (2016)

–

–

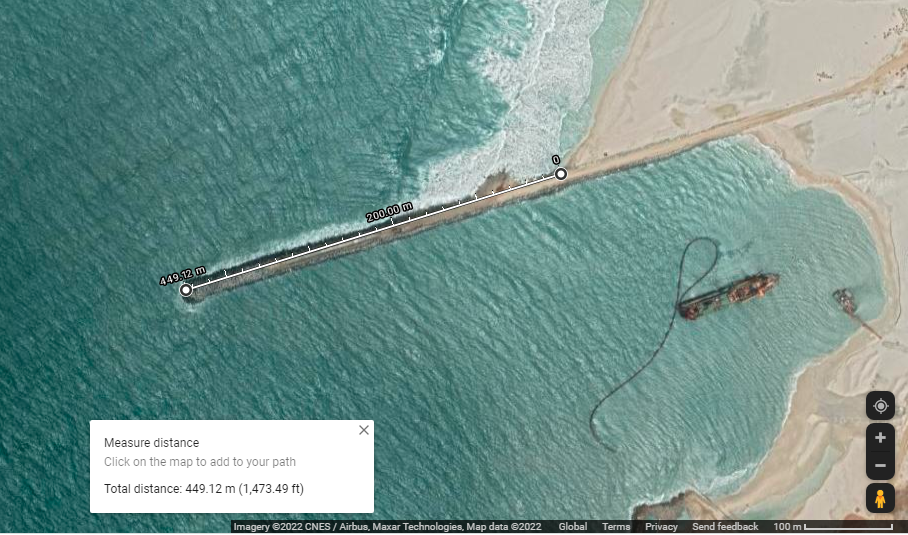

4. Port of N’diago

–

Ndiago or N’Djiago is a town and urban commune in the Trarza Region of south western Mauritania.

Coordinates: 16°10′N 16°30′W

Availability of electricity per capita 30% est.

–

Port of N’diago Breakwater

breakwater ( meter ) = 450 m

The average wave power on the coast (kw/m) :

17.5 (Kilowatt /meter)

The total wave energy per year on the breakwater and the berth :

69,000 (MWh/year)

The efficiency of wave energy conversion 30% with using 100% of breakwater length :

20,700 (MWh/year) ~ 1.95%

of the total electricity consumption 1,059,000 MWh (2016)

–

–

Conclusion: Wave energy can produce 10% of the total annual electricity consumption in Mauritania, if the breakwaters in Mauritanians ports are used as platforms to install wave energy convertors , about 100,000 (MWh/year) .

–

Wave energy potential in Belgium

–

–

The total coastlines of Belgium :

65.5 km on the North Sea

Coastal population percentage :

32%

The average wave energy :

7.5 KW/m

Wave energy theoretical potential :

4.30 TWh/y

Wave energy applicable potential :

0.21 TWh/y

Total electricity consumption:

79.83 TWh (2016)

Tide & Wave energies sharing to the total electricity production :

0 MWh (0.00%)

Wave energy index : wave energy applicable potential % Electricity consumption

0.26%

Wave energy potential in Poland

–

–

The total coastlines of Poland :

770 km on the Baltic Sea

Coastal population percentage :

50%

The average wave energy :

2.5 KW/m

Wave energy theoretical potential :

17 TWh/y

Wave energy applicable potential :

0.90 TWh/y

Total electricity consumption:

156.91 TWh (2016)

Tide & Wave energies sharing to the total electricity production :

0 MWh (0.00%)

Wave energy index : wave energy applicable potential % Electricity consumption

0.60%